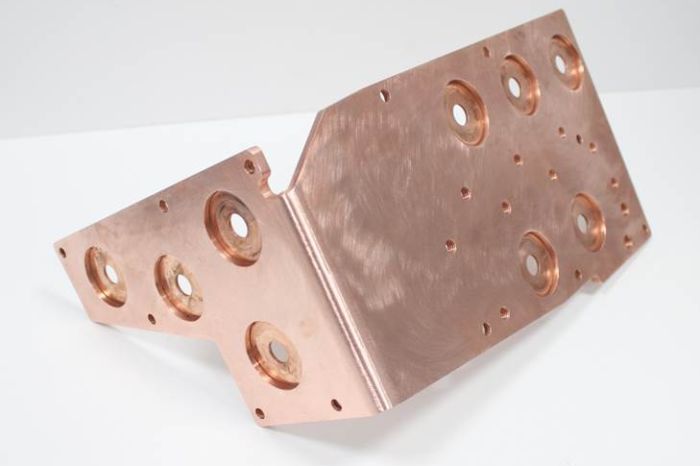

MANAGEMENT AND TRACKING OF A FINISHED PRODUCT

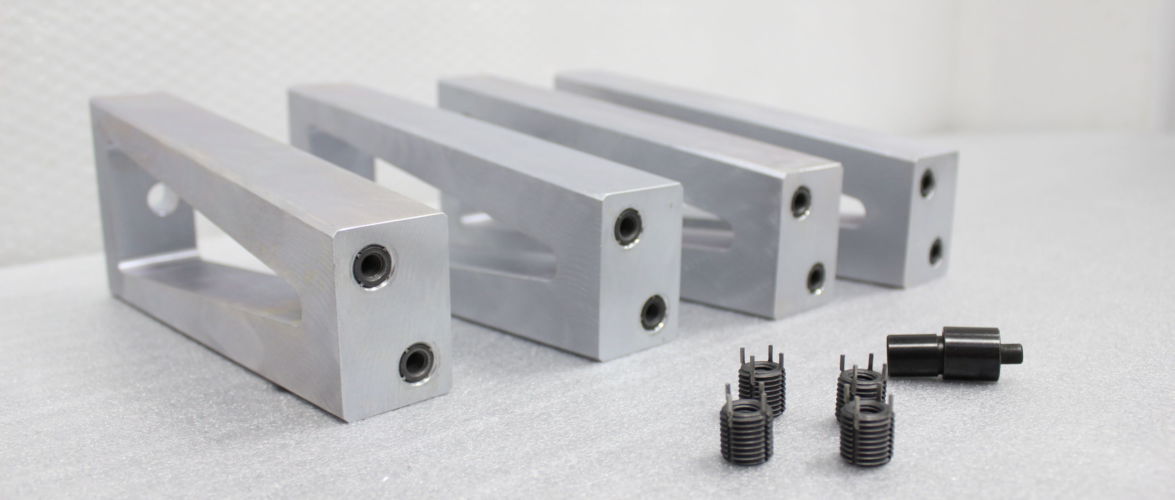

We have the processes and qualified people to manage and follow up other processes such as the purchase of raw materials, treatments, painting, etc..., until we offer a finished product to the customer.

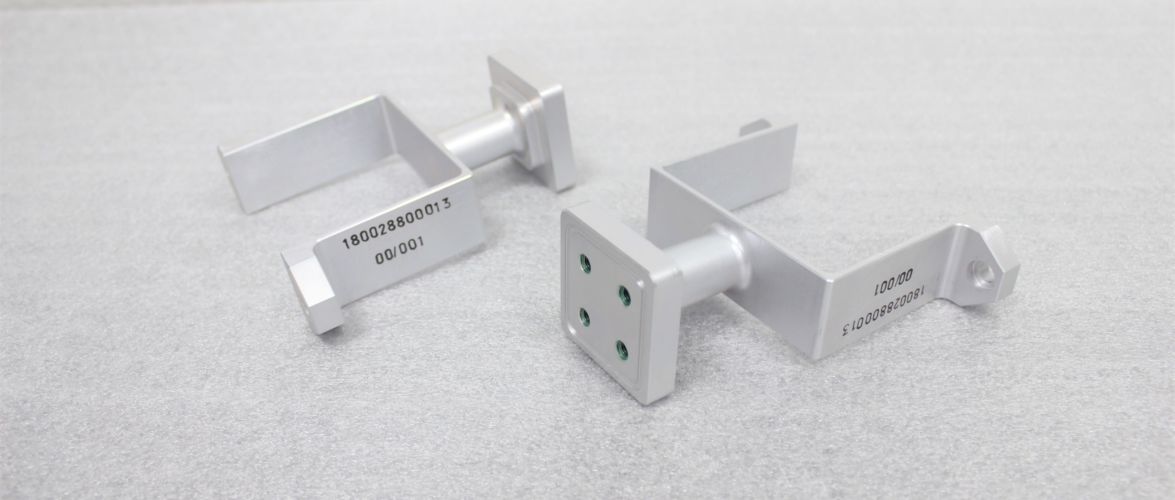

MANUFACTURABILITY

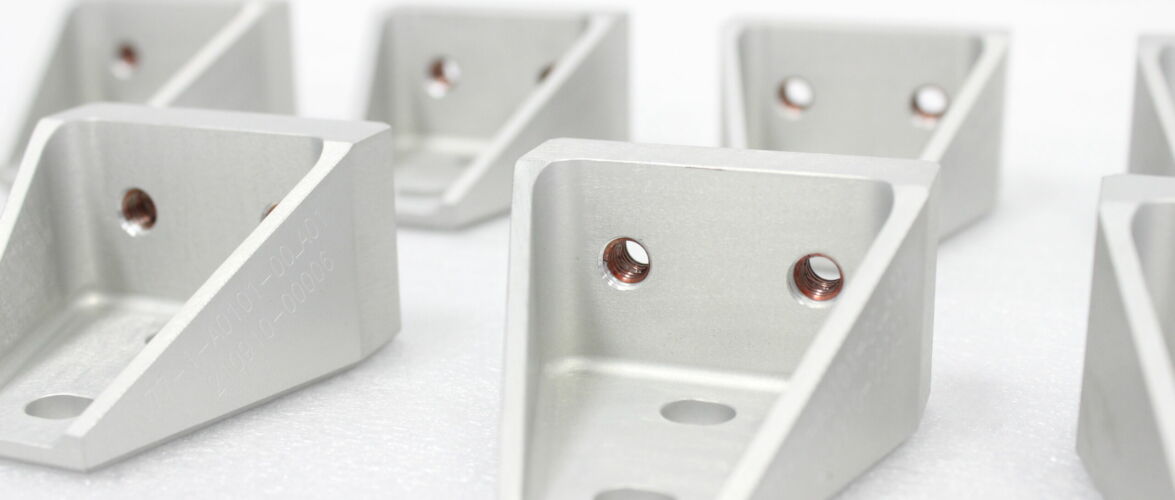

Extensive knowledge and experience

We offer our knowledge and experience to study and analyze the manufacturability of complex precision elements, reporting to the customer the feasibility of the design and the technological and economic applications necessary for their manufacture.

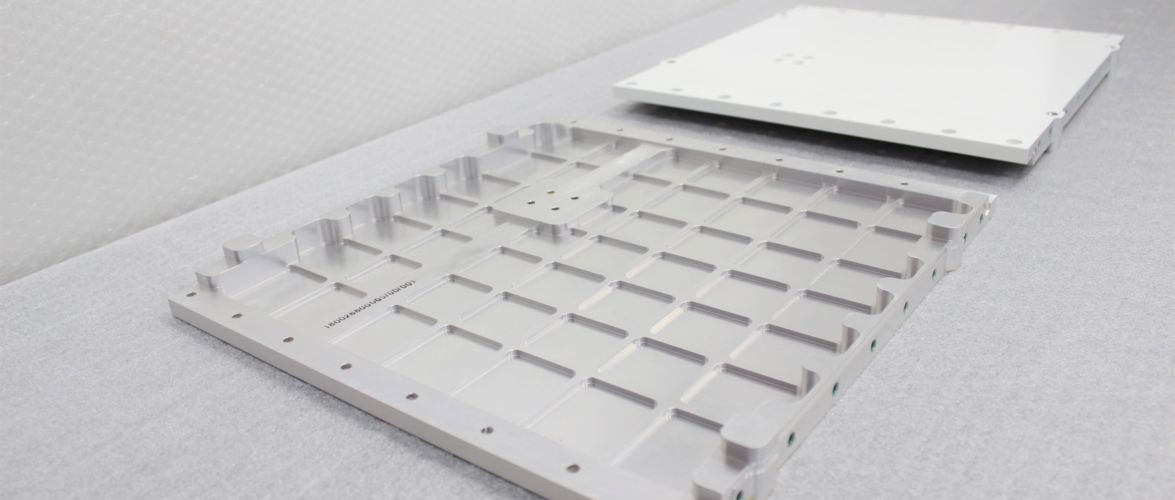

INDUSTRIALIZATION

Every day a new piece

Years of experience and a large list of references support us, we industrialize an average of 10 to 25 new references per month.

A team of professionals is continuously taking on new references of different materials and geometries.

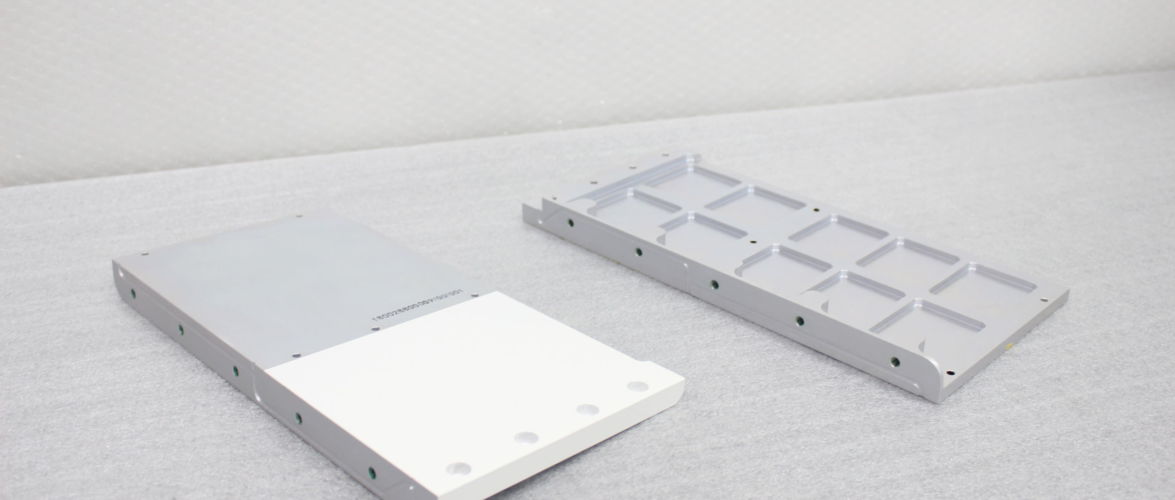

PRODUCTION

We do not fail in your planning

Our 24-hour production system allows us to offer reduced delivery times to avoid impacting our customers' schedules.

An operator maintains a continuous analysis and management of the status of each reference and the time remaining for its delivery, having a view of the delivery in advance.

VERIFICATION

QUALITY CONTROL

Continuous quality control over production ensures an effective manufacturing flow, maintaining a high level of efficiency and low level of downtime.

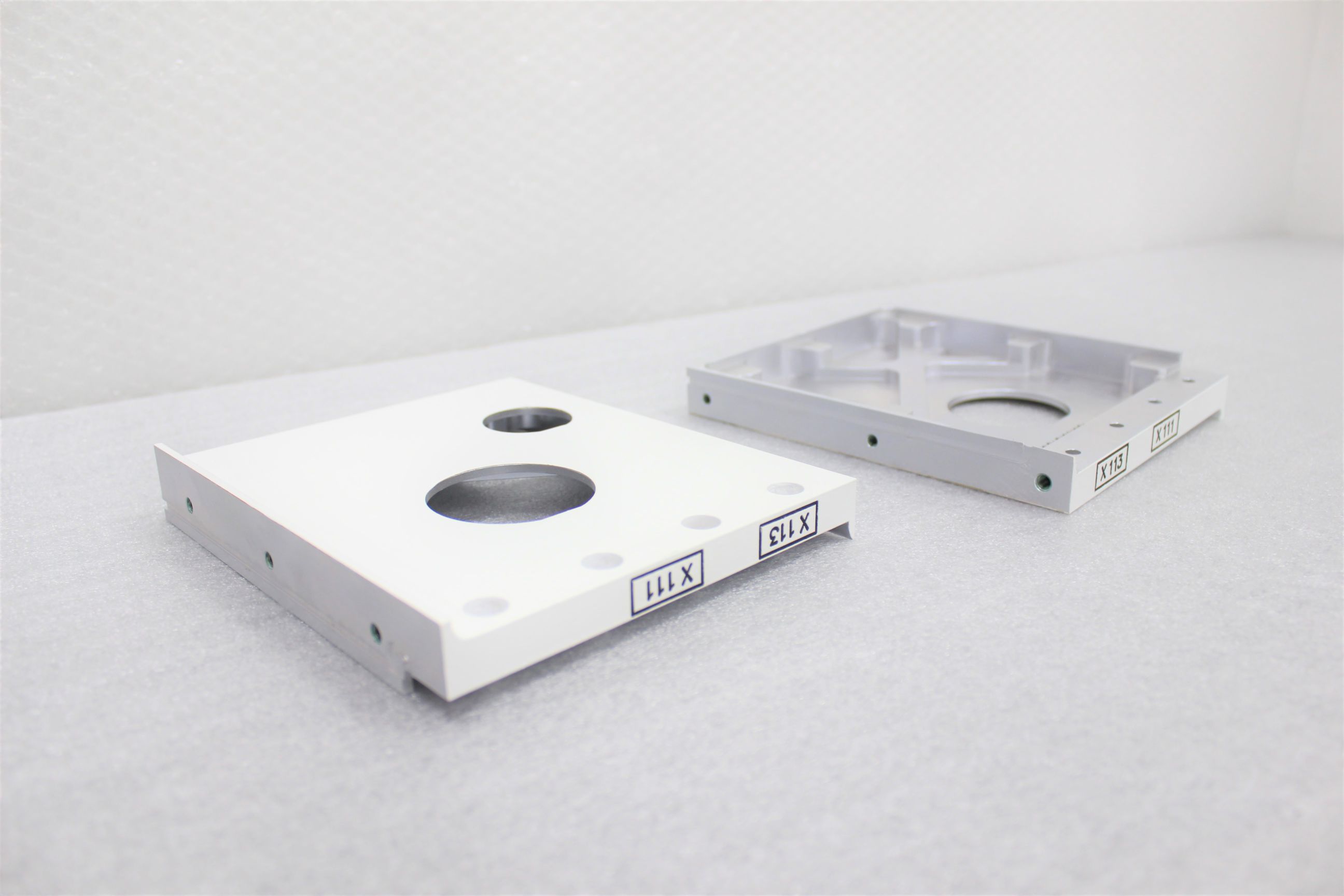

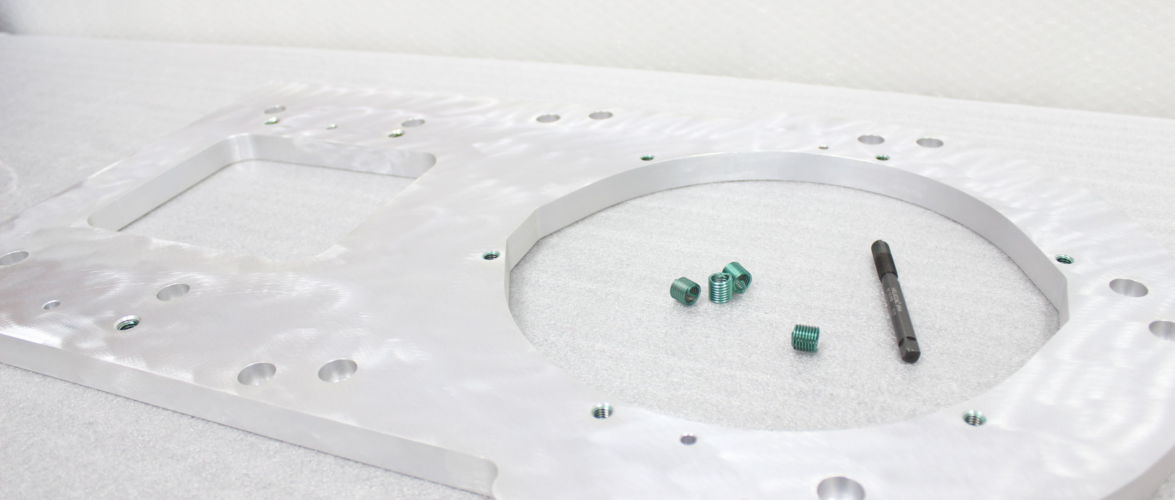

FINISHES

ATTENTION TO DETAIL

We perform different finishes or manual finishes to achieve the result that the customer wants.

ATTENTION & SATISFACTION

Our ENGINEERING department is in continuous contact with the project managers to transfer difficulties, observations and information about the contracted elements, maintaining a permanent communication and anticipating any unforeseen event.